*Please note* - whilst the custom motor is similar to a Nema 17, it isn’t a standard Nema 17. Hemera's heatsink design ensures airflow is diverted up and away from both the HotEnd and the heated bed, reducing the risk of warping and uneven stresses forming in the printed part. But trust E3D - the performance is second to none and also has a significant impact on printing normal materials such as PLA or PETG. You won’t truly ‘get’ the impact of the optimized constraint that Hermes provides until you’ve printed flexibles with it. Hemera constrains your filament like no other hotEnd/extruder combination. It’s the easiest, most feature-rich direct drive platform available for your Creality 3D printer, with no firmware coding or permanent modifications required.

#Hemera extruder ender 3 upgrade

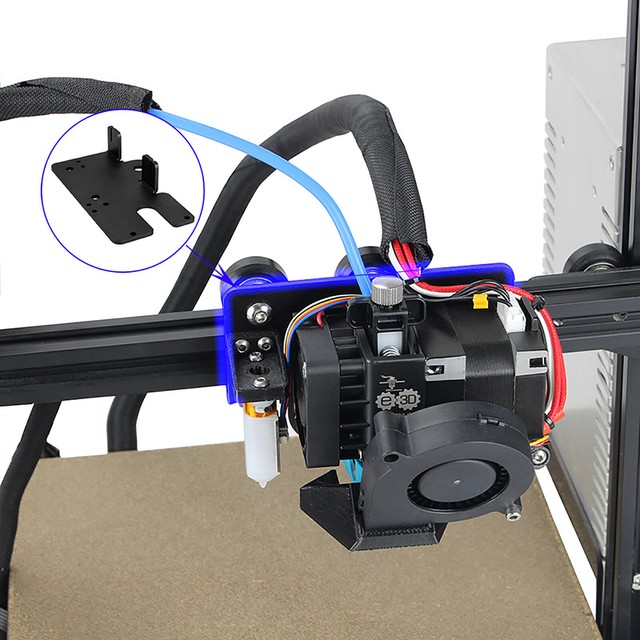

This is neat as it allows E3D to use the motor itself as part of the assembly and to add their own features for the user’s convenience, such as the mounting T-Slots. Creality Ender 3 Direct Drive upgrade kit: Instantly improve print quality, simplify retractions and filament changes, and easily print any material with the MDD v1.3. To achieve this, E3D has developed a custom motor, based on a NEMA17 frame, with their own faceplate designs. Hemera is a system of components designed to work seamlessly together as a single product. The round bottom of the profile strongly resists filament debris wedging into the drive gear and in almost all cases it’s self-cleaning as any debris simply falls off the teeth.Į3D set out to develop a compact extruder and HotEnd system with a reduced part-count. Individually CNC cutting each hobb allows for a round-bottomed root, with a tooth that curves upwards to a robust, sharp tip. Featuring dual drive gears, auto-loading compatibility, and fantastic grip strength providing a reliable extrusion system that minimizes slipping and grinding.Į3D Hemera is a dual-drive system with a hardened stainless steel drive train. (via Canada Post)Į3D Hemera (formerly known as Hermes) is a powerful next-generation extruder. and fan duct for the Artillery (Evnovo) Sidewinder X1 and the E3D Hemera.

Also, the linear rail needs to be moved to the right (viewed from the front of the printer) for the nozzle to reach the whole bed.Free shipping in Canada for orders over $140 before tax. 51 30 OFF Buy For Ender3 Direct Extruder Kit Titan Extrusion Hotend Kit MK8.

There are some nice designs on Thingiverse.Īs a downside, you have to relocate the x-axis endstop switch. On the opposite side of the Hemera/Hermes, you can mount any generic bed leveling sensor mount and fan duct. It includes a 30 mm long outlet to fix the bundle of wires that exits the x-carriage with two zip-ties. There are three attachment points for zip-ties that allow you to neatly mount the heater cartridge and thermistor wires I cut a channel that allows you to rout the hot end fan wires between the Hemera/Hermes and the adapter bracket (For the one screw that goes through the belt bracket, you have to shorten a M3x20mm screw to 18mm or use some shims under the screwhead - this is important as using a screw which is too long will damage the Hemera/Hermes) The adapter bracket is thick enough to allow the usage of three M3x8mm screws supplied with the Hemera. The Hemera/Hermes is mounted in a way that produces minimum flex in the adapter bracket The hole is highlighted in screenshot #2. (Attention: you have to drill out (try a 3mm drill first or a 3.5mm if you have one) the center hole of the aluminium part to make it a through hole for an M3 bolt. It re-uses the x-axis belt bracket supplied with the BLV upgrade kit so the belt can be properly tensioned. The design emphasises the mechanical strenght of the whole assembly:

#Hemera extruder ender 3 pro

This mount is designed for the BLV Ender 3 Pro upgrade that uses an Hiwin MGN 12H linear rail on the x-axis. This design is still being tested by me - any feedback for improvement is welcome

0 kommentar(er)

0 kommentar(er)